The Beacon 3000 is an inline, multi-channel Process NIR Analyzer. It enables non-contact, real-time monitoring and closed-loop control of physical properties and chemical composition in industrial process applications.

The Beacon 3000 NIR analyzer is ideal for monitoring petroleum, chemical, and petrochemical products. Based on novel algorithms, the Beacon 3000 measures the absorption spectrum in the near-infrared (NIR) quickly and accurately without labor and material waste. The system\’s versatile software models enable soft switches between different chemistries. With the capability to monitor up to eight Flow Cells in parallel, the Beacon 3000 provides efficient, low-cost per-channel process monitoring. When integrated into a control system, the Beacon 3000 enables tighter process control and identifies process excursions before they affect yield.

Features & Benefits of Beacon-3000 NIR Analyzer

- The Main NIR Analyzer is located in the Control Room, protected from the process environment. The Main NIR A

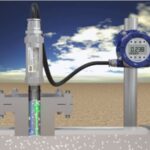

- nalyzer connects, via telecommunications fiber optics, to the Field Units, that are installed up to 3 km (2 miles) away, close to the process. Up to 8 Field Units can be connected to one Main Analyzer.

- The Field Unit uses no electricity and contains no moving parts. This 100% optical probe requires no explosion-proof housing or analyzer shelter. The Field Unit is certified under the ATEX Directive 94/9/EC (EN 60079-28:2007).

- In many applications, the Beacon 3000 Process NIR Analyzer’s performance and price make it an attractive alternative to traditional analyzers, such as gas chromatographs or distillation analyzers. No analyzer shelter is required, and the low maintenance requirements reduce ownership costs to a minimum.

For further details and specifications

Choose the PDF files to download

[/vc_column_text][/vc_column][/vc_row]

Measured properties include:

- Motor Octane (MON)

- Research Octane (RON)

- Distillation Points (IBP, T10, T50, T90, FBP)

- PIONA

- API Gravity

- Cloud Point

- Flash Point

- Pour Point

- Cetane index

- Reid Vapor Pressure

- Viscosity

- Chemical Composition

- Total Aromatics

- Total Olefins

- % Benzene

- % para Xylene

- % meta Xylene

- % ortho Xylene

- % MTBE

- % Oxygenates

- and more …

Frequently Asked Questions about Beacon-3000 NIR Analyzer

What is NIR analysis and how does the Beacon 3000 NIR Analyzer utilize it?

NIR (Near Infrared) analysis measures the absorption spectrum in the near-infrared region. This method is crucial for non-contact, real-time monitoring of physical properties and chemical compositions. The Beacon 3000 NIR Analyzer harnesses this technology to provide fast and accurate assessments without the need for labor-intensive laboratory procedures or material waste, making it essential for process industries aiming to enhance efficiency and quality.

How does the Beacon 3000 improve monitoring in petroleum, chemical, and petrochemical applications?

The Beacon 3000 is specifically designed for monitoring complex substances such as petroleum, chemicals, and petrochemical products. It enables real-time, inline monitoring and closed-loop control of processes, ensuring that any deviations in the desired chemical composition or physical properties are promptly detected. This capability allows for tighter process control, preventing potential yield impacts and optimizing production efficiency.

What are the main features and benefits of the Beacon 3000 NIR Analyzer?

Key features of the Beacon 3000 include its ability to connect up to eight Field Units from a distance of up to 3 km (2 miles) via telecommunications fiber optics. The Field Units operate without electricity and have no moving parts, requiring no explosion-proof housing. The system’s versatility and low maintenance make it a cost-effective alternative to traditional analyzers like gas chromatographs, reducing overall ownership costs while enhancing safety and operational efficiency. FreeTune software provided with the analyzer enables automatic model updates based on laboratory data analysis.

How does the Beacon 3000 ensure safety and compliance in hazardous environments?

The Beacon 3000’s Field Unit is designed to be inherently safe, complying with ATEX Directive 94/9/EC (EN 60079-28:2007). This means it can safely operate in explosive atmospheres without requiring special housing and environmental control for the analyzer. This 100% optical probe setup eliminates the risk of sparks and allows for installation in volatile environments, ensuring safety and compliance with stringent industry standards.

Can the Beacon 3000 NIR Analyzer handle multiple process streams?

Yes, the Beacon 3000 can monitor up to eight Flow Cells simultaneously. This multi-channel capability allows it to handle multiple process streams, enabling comprehensive monitoring and optimization of various chemical processes within a single system. This feature particularly benefits facilities that manage diverse process reactions and require consistent quality control across different production lines.

What makes the Beacon 3000 a cost-effective solution for process monitoring?

The Beacon 3000 NIR Analyzer reduces the need for traditional, more expensive discrete analytical methods, such as distillation analyzers. Its low maintenance requirements and the absence of electrical components or moving parts in the Field Units significantly decrease the cost of ownership. Additionally, the system’s robust performance and flexibility in different integration processes help reduce operational costs and improve economic efficiency.

How can I obtain more information or technical specifications about the Beacon 3000 NIR Analyzer?

For detailed information and technical specifications about the Beacon 3000 NIR Analyzer, interested parties can download various PDF files available on our website. These documents include comprehensive details about different applications, such as the Beacon 3000 for Gasoline and Diesel blending, aromatic complexes, alkylation processes, ethylene crackers, and more, enabling potential users to understand how the analyzer can be integrated into specific processes to optimize production and safety.